Available industries: Power generation, Heating, Chemical, Food, Rubber.

Available fuel: Bituminous,Coal,Biomass;

Working pressure: 1.25-5.4 MPA;

Thermal power: 20-75t/h;

Output water temperature: 184-485°C;

Shipping ports: Shanghai, Qingdao or Tianjin;

Delivery: 30-45 working days;

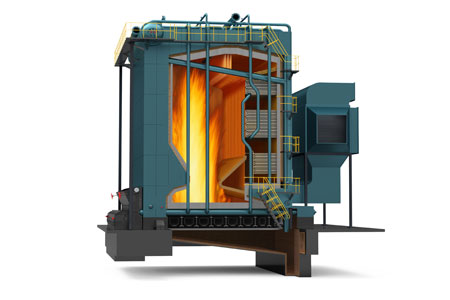

The corner tube boiler uses a piping system as the skeleton of the entire boiler, and it bears the full load of the boiler, which makes a non-framework boiler. At the same time, this skeleton also serves as the down tube of the boiler and upper and lower headers.

The boiler drum is an external type drum, the furnace is a fully enclosed membrane wall structure, the convective heating surface adopts the flag structure. The corner boiler has the advantages of compact structure, low steel consumption and rapid temperature increase, which makes the boiler very popular. The boiler is field assembled boiler.

Feature

1. The boiler adopts a unique water circulation structure, the drum is free from heat and the heated water flows in one direction.

2.Corner tube boiler adopts non-framework structure, body weight is supported by membrane water wall and down tube, and all membrane walls are all welded into one whole, with good anti-seismicity.

3. All around the boiler body is made of welded membrane water walls, and the steel structure is completely sealed to prevent the occurrence of air leakage.

| Model | DHL35-1.25-M | DHL50-1.25- | DHL75-1.25-M | ZZ-35/3.82-M |

ZZ-50/3.82-M |

ZZ-65/3.82-M | ZZ-75/3.82-M |

ZZ-75/5.3-M |

| Rated thermal power(t/h) | 35 | 50 | 75 | 35 | 50 | 65 | 75 | 75 |

| Rated working pressure(MPA) | 1.25 | 1.25 | 1.25 | 3.82 | 3.82 | 3.82 | 3.82 | 5.3 |

| Rated imported water temperature(°C) | 194 | 194 | 194 | 450 | 450 | 450 | 450 | 485 |

| Feed water temperature(°C) | 105 | |||||||

| Fuel available | Bituminous coal, biomass | |||||||

| Design efficiency(%) | 89 | 89 | 89 | 89 | 89 | 91 | 91 | 91 |